Construction equipment brain repair service is usually a field that requires special skills and experience. Construction equipment usually contains complex electronic systems and control modules. These systems manage the engine performance, hydraulic systems, electrical components and other important functions of the construction equipment.

Brain repair service includes the following main elements:

Troubleshooting:The first step is to identify the problem that is causing the machine to malfunction or lose performance. This is usually done by specialized diagnostic equipment and experienced technicians.

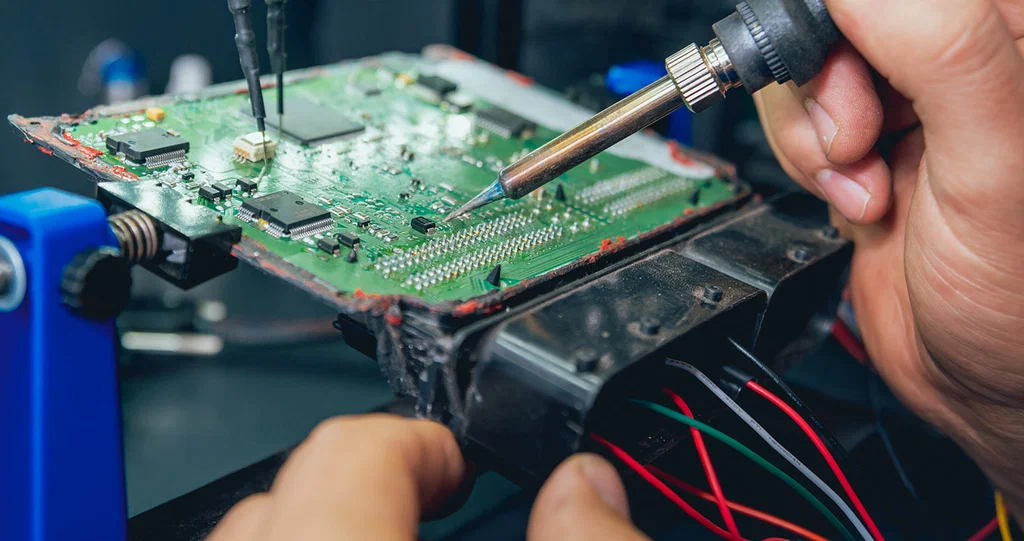

Component Repair or Replacement: Electronic components or control modules identified as the source of the fault may be repaired or completely replaced. This should be done in accordance with the manufacturer’s recommendations and specifications.

Software Updates: The control systems of the machine are usually software-based and may need to be updated from time to time. During the brain repair, the updated software may need to be installed or adjusted.

Performance Tests and Tuning: After repair, performance tests are performed to ensure that the machine is operating properly again and adjustments are made as necessary.

Certification and Warranty: The repair process and parts used are usually documented. This can affect whether the machine is under warranty, so authorized service centers usually manage these processes.

Construction equipment brain repair is a critical service in terms of safety and performance. Therefore, it is generally recommended that it be done by technicians trained and certified by the construction equipment manufacturer or by authorized service centers. This is important to ensure the long-lasting and reliable operation of the construction equipment.